How To Repair A Leaking Grey Water Tank On An Rv

Instructional Video No. one

Instructional Video No. 2

Step-By-Stride Instructions

Step one

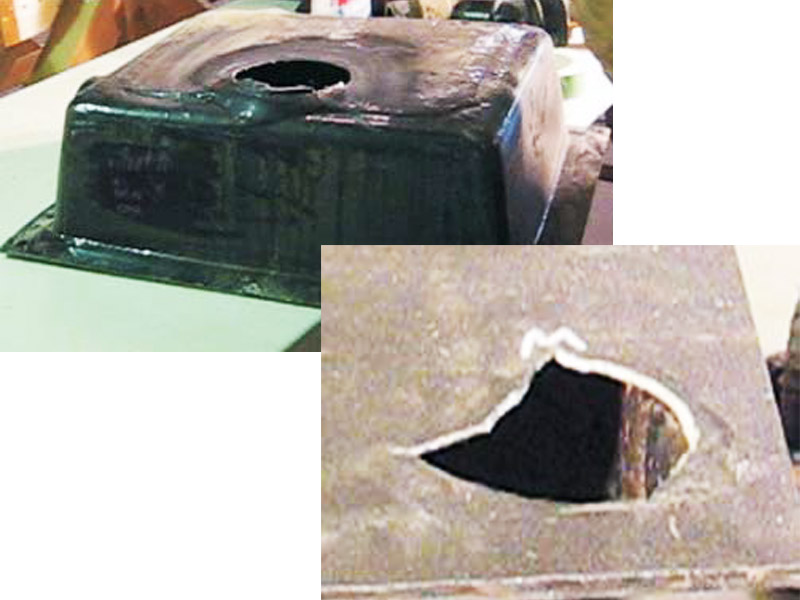

Lay out all cleaved pieces making certain that all parts are clean and dry. Dry out fit the pieces back together and make sure they will fit. If needed trim pieces to make the fit equally close every bit possible. If in that location are missing pieces utilize the supplied ABS sail stock to replace missing pieces. Additional ABS sheet stock is available in a five 1/2" X 9 i/2" ii pack.

Step 2

Fit the pieces together if needed use masking tape to hold them in place. If you are using a apartment patch mark the area with tape so yous know where to put the resin. patches tin can be heated and formed to curves. see folio 2. Brand certain the expanse to be repaired is make clean and dry. Apply a file, wire brush, or dremel tool to remove all impurities downward to the raw plastic.

Step 3

With the pieces, fit and secure begin applying a heavy dewdrop of resin to the cracks. If y'all have used tape to secure the parts get out those areas until the outset application is cured. The resin is a single role with no mixing needed information technology air cures in about 24 hours. If you are using a apartment patch put chaplet of resin effectually the hole such that there volition be no path to the outside edges nether the patch. Heavy applications may demand more than 24 hours to cure.

Step 4

Go on to build up the repair with resin. If you have used tape on the first application remove it and advert resin to those areas. The heavier the awarding the longer the air cure volition take. If you have used a flat patch put the patch down and press it firmly into the resin. If needed use a weight or apply record to the edges to make sure the patch stays tight to the tank.

Pace 5

Leaks in the ABS plumbing piping tin also be hands repaired with the resin. Clean the leaking area with a wire brush. Remove any water (toilet paper works well). Utilize the resin to the leaking plumbing fixtures. Expect 24 hours to exam the repair

Step six

The ABS sheet stock tin can be formed to curved areas. Put the sheet into an oven set at 150-250 degrees or into a pan of humid water for ten-15 minutes. Use gloves and remove the sail. It is ready when it is equally flexible as a sheet of paper. Either hold it to the curve or tape it until it cools. One time cool use it to make the repair.

Footstep 7

Look around your RV, Auto, and Home for other plastic items to repair. To test if the plastic is ABS and reparable find a subconscious spot and scrape downward to raw plastic. put a drib of resin on the raw plastic. in 24 hours if you lot can't choice of the resin the plastic is ABS and is repairable. There are examples of ABS plastic on our website www.easyabsrepair.com

Step 8

When your repair is complete think to remove the applicator tip and put the white seal cap back on. this will ensure the bottle is sealed and volition keep it'south shelf life. Set the applicator tip bated and in 36 hours the resin will harden and autumn out and the tip is prepare to utilize once more.

Subscribe to my Youtube aqueduct for how-to videos

Source: https://easyabsrepair.com/abs-plastic-repairs/rv-repair/

Posted by: pittmanwarme1974.blogspot.com

0 Response to "How To Repair A Leaking Grey Water Tank On An Rv"

Post a Comment